Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

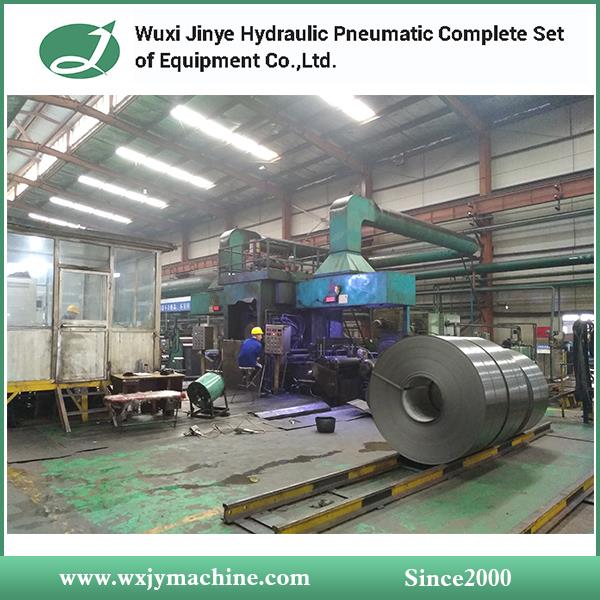

Six roller (6-hi) cold rolling mill introduction 6-Hi rolling mill is especially suitable for high precision rolling at high rolling speed, can give a variety of finished thicknesses, reducing steel coil strip from 3mm to 0.10mm with width ranging from 500 to 1250mm.Different materials and...

Six roller (6-hi) cold rolling mill introduction

6-Hi rolling mill is especially suitable for high precision rolling at high rolling speed, can give a variety of finished thicknesses, reducing steel coil strip from 3mm to 0.10mm with width ranging from 500 to 1250mm.Different materials and different states of metal plates require different rolling processes, the cold rolled plate precision level decides the rolling mill configuration, the yearly or monthly production decides the rolling capacity and rolling speed.We design each cold rolling mill based on precise calculation of rolling process required by each client. Customers trust us because we make the rolling mill exactly as what they want.

The main composition of a reversible six high rolling mill line

Uncoiler, coil-head opener, pinch rollers and seven roller leveler, left recoiler, entrance processing table, 6-hi cold rolling mill, exit processing table, right recoiler.

Composition of a 6-hi cold rolling mill

Rollers: one pair of work rollers(upper work roller and lower work roller) , one pair of middle rollers( one upper middle roller and one lower middle roller), and one pair of backup rollers(one upper backup roller and one lower backup roller)

Rolling stand: Two stands pair well and are connected oppositely, To process the pair of stands wholly, manually shovel the surface to be flat, with sliding plate at window.

Press-down equipment: hydraulic AGC.

Drive mechanism: motor, speed reducing gearbox and distribution gearbox.

Control: DC speed driver, encoder, PLC, tension control

Typical 6-Hi rolling mill models

1) Ø145×600/Ø195×600/Ø550×570 reversible 6-hi cold rolling mill.

Application:≤500mm width, output ≥0.1mm thickness, for pickled plain carbon steel coil strip(tensile strength 350-500Mpa).

Work process and Production:

uncoiling → uncoiling → pinch feeding & straightening

↓

Left recoiling←→6-hi reversible rolling mill←→Right recoiling → Coil discharging car

Input Steel coils:

Steel material: plain carbon steel, pickled, etc.

Tensile strength 350~500 Mpa, yield strength 195-240Mpa

0.8~2.0 mm thickness

300~500mm width

Max outer diameter: 1700 mm

Inner diameter: 508mm

Max coil weight: 8t

Output: 0.1~0.5× 300~500mm

Inner diameter of recoiled coil: 508mm

Machine Parameters:

Max rolling force: 4500 KN

Rolling torque: 25KN.m

Rolling speed: max 500 m/min

Recoiling speed: max 530 m/min

Recoiling force: 45 KN

Height of rolling mill workline: 1000 mm

Total installation power: about 1900 KW

2)φ185×850mm/φ320×850mm/φ760×820mm 6-Hi Reversible Cold Rolling Mill 600m/min

Input Raw Material:

Hot rolled steel coil after being cleaned by pickling, either edge trimmed or not

Low carbon or medium carbon steel, low alloy steel

Steel grade: Q195-Q235; 08Al; SPHC; SPHD; SPHE

Tensile strength: max 450N/mm²

Yield strength: 140-360N/mm²

Coil Thickness: 1.5-3.0mm.

Coil width: 500~750mm

Coil ID: φ508mm

Coil OD: φ800~φ2000mm

Max coil weight: 18t

Finished Coil -Cold Rolled Coil:

Finished thickness: 0.2~0.8mm

Finished width: 500~750mm

Max thickness reducing degree: total thickness reduction of different hardness material is different. Q195≤91% Q235≤90% Q345≤85%

Rolling precision:

(“δ” as the finished thickness)

Thickness tolerance in longitude: | |

Stable rolling | ≤±2%δ |

Acceleration or Deceleration rolling | ≤±3%δ |

Max rolling pressure: 7000 KN

Max rolling torque: 90 KN.m

Max rolling speed:600m/min

Max uncoiling speed: 200 m/min

Max recoiling speed: 660m/min

Uncoiling tension: max 40kn

Recoiling tension:10-70KN

Uncoiling mandrel diameter(expand, compact): φ520/φ470mm

Recoiling mandrel diameter(expand, compact) : φ508/φ485mm

Rolling stand section: 450×550mm2

Minimum opening of work rollers: 20mm

Positive/negative roller bending force(each side of each work roller) : +150kn/-80kn

Positive roller bending force(one side of each middle roller) : 300kn

Transverse transfer of middle roller: +120mm for upper middle roller, -120mm for lower middle roller

Systematic pressure of general low-voltage hydraulic system: 0mpa

Systematic pressure of roller bending hydraulic system: 18.5mpa

Systematic pressure of Hydraulic AGC system: 23mpa

Total installation power: 2800KW

Height of rolling line: 1000mm

2) φ280×1380mm/φ380×1350mm/φ1050×1350mm Six Roller Reversible Cold Rolling Mill 720m/min

Input Raw Material:

Hot rolled steel coil after being cleaned by pickling, either edge trimmed or not

Low carbon or medium carbon steel, low alloy steel

Steel grade: Q195-Q235; 08Al; SPHC; SPHD; SPHE

Tensile strength: max 450N/mm²

Yield strength: 140-360N/mm²

Coil Thickness: 2.5-4.0mm.

Coil width: 1000~1250mm

Coil ID:φ610mm

Coil OD:φ800~φ2000mm

Max coil weight: 25t

Finished Coil -Cold Rolled Coil:

Finished thickness: 0.2~0.3mm

Finished width: 1000~1250mm

Machine Parameters

Max rolling pressure: 14000 KN

Max rolling torque: 120 KN.m

Max rolling speed: 720m/min

Recoiling tension: 170KN

Recoiling mandrel diameter(expand, compact):φ610/φ585mm

Rolling stand section: 540×640mm2

Minimum opening of work rollers: 20mm

Positive/negative roller bending force(each side of each work roller): +300kN/-180kN

Positive roller bending force(one side of each middle roller): 500kN

Transverse transfer of middle roller: +150mm for upper middle roller, -150mm for lower middle roller

Total installation power: 10000KW

Configuration

Hydraulic AGC press-up system with automatic control, including hydraulic press-up cylinders, AGC control system, hydraulic station, thickness gauges, with functions of constant roller clearance position control, constant pressure control and automatic tilt adjusting control.

Hydraulic AGC press-up system with automatic control, including hydraulic press-up cylinders, AGC control system, hydraulic station, thickness gauges, with functions of constant roller clearance position control, constant pressure control and automatic tilt adjusting control.

CPU computer automatic control system

CPU computer automatic control system

HIM touch screen for dynamic display, rolling parameters setting, breakdown alarms and report printing

HIM touch screen for dynamic display, rolling parameters setting, breakdown alarms and report printing

Digital DC drive

Digital DC drive

Drive middle rollers (separately drive upper middle roller and lower middle roller

Drive middle rollers (separately drive upper middle roller and lower middle roller

Rollers cooling control divided in five zones , emusified water flow control

Rollers cooling control divided in five zones , emusified water flow control

Work roller positive/negative bending control

Work roller positive/negative bending control

Presetting of middle roller transfer and middle roller positive bending control

Presetting of middle roller transfer and middle roller positive bending control

Zero setting of rolling centerline by wedge

Zero setting of rolling centerline by wedge

Work rollers and middle rollers fast changing equipment

Work rollers and middle rollers fast changing equipment

Automatic adjustment of rolling speed and tension

Automatic adjustment of rolling speed and tension

Protection measures in case of strip break, accidents alarms and emergency stop

Protection measures in case of strip break, accidents alarms and emergency stop

Oil gas lubrication for work rollers, middle rollers and backup rollers

Oil gas lubrication for work rollers, middle rollers and backup rollers

Roller bearings for backup rollers

Roller bearings for backup rollers

X-ray thickness gauge

X-ray thickness gauge

Rolling process linkage and defect alarms controlled by PLC

Rolling process linkage and defect alarms controlled by PLC

The presetting of rolling process, the inspection, display and alarm of rolling process parameters and critical machine parameters

The presetting of rolling process, the inspection, display and alarm of rolling process parameters and critical machine parameters

FAQ

1.Are you a manufacturer, trading company or a third party?

A: We are a manufacturer established in 2000.

2.As the shipping period will take long time, how can you make sure the machine won’t be broken?

A: Our machine is film wrapped, to make sure the machine can be delivered to our customer in safe conditions, we fix the machine in the container by steel wires / ropes.