Introduction:

This high-speed cut-to-length line is able to uncoil & level a coil strip, and then shear the leveled flat strip to certain length of sheets at line speed of max 100m/min. It is referred as coil strip CTL machine in general place. This CTL machine is suitable for thin sheet or thin coil cut-to-length.

The high speed cut-to-length line adopts servo length-fixing and pneumatically mechanical shearing to make sure sheet length precision and clean shearing notch.

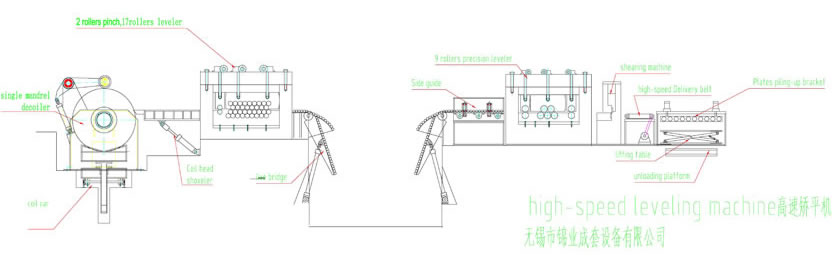

The coil strip high speed cut-to-length line (CTL machine) is composed of: coil loading car, single-mandrel decoiler, coil-head guide, press & shoveling equipment, pinch-feeding roller & leveling machine, hole accumulator, side guide, fine leveling & length-fixing machine, pneumatically mechanical shearing machine, delivery belt, piling-up bracket, up-down lifting table, moving-out car, hydraulic system and electric control system.

The high speed CTL machine (coil strip cut-to-length) fit steel coils with thickness: (0.2-2mm, 0.3-3mm, 0.6-4mm, or 1-5mm) and changeable width and length of finished sheets depend on customer's practical need.

Advantages and Characteristics of Coil Strip Cut-to-Length Line:

1. Fast speed and high precision

Line speed can be up to 100m/min, 25-30pcs/min 2000mm Length sheets in average.

Leveling precision: ±1mm/㎡

Sheet length precision: ±0.5mm/m

Sheet diagonal length precision: ±0.5mm/m

2. Thin coils differ in coil weight, when max coil weight is small, usually single mandrel (cantilever) uncoiler for this high-speed cut-to-length line is adopted.

3. To make flat steel sheets, the diameter of leveling rollers should be scientifically proper, we confirm diameter of leveling rollers by actual experiences and engineering calculation.

4. Automatically piling-up bracket can receive finished sheets and automatically pile them up orderly.

5. Hole accumulator between leveling machine and fine leveling, is necessary to protect sheet surface and make sure the simultaneously work of leveling machine DC motor and fine leveling servo motor.

High-Speed Cut-To-Length Line

|

Detail specification: Model |

thickness | width | Length | Leveling speed |

| JY-2 x 1000 | 0.2-2.0mm | 400-1000mm | adjustable | Max 100m/min |

| JY-3 x 1250 | 0.3-3.0mm | 500-1250mm | adjustable | Max 100m/min |

| JY-4 X 1500 | 0.6-4mm | 500-1500mm | adjustable | Max 80m/min |

| JY-5x1600 | 1-5mm | 500-1600mm | adjustable | Max 80m/min |

| Note: The data in the form just as reference according to general ranges, we always design and make each line according to each customer's specific requirements, so each customer can buy his own well-content CTL Machine line from us. | ||||